Engine/Internal (Five Items)

Product Name: Piston Rings

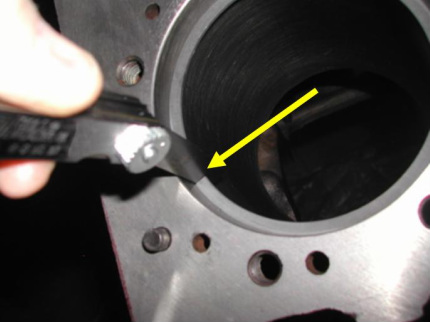

Product Description: When rebuilding an engine, the piston rings should always be replaced. The piston rings help seal the compression inside of the combustion chamber during the four stroke cycle. They also help scrape the oil off of the cylinder walls below the piston. One check that is important is called piston ring end gap. As shown in the photo to the left, it is the amount of clearance between the two ends of the compression rings. This clearance should always be checked with a feeler gauge and compared to the manufacturer's specifications. As the compression rings wear over time, this end gap increases. As it increases, more compression gases escape. This causes the combustion to be less efficient as well as having increased crankcase

pressure.

Product Description: When rebuilding an engine, the piston rings should always be replaced. The piston rings help seal the compression inside of the combustion chamber during the four stroke cycle. They also help scrape the oil off of the cylinder walls below the piston. One check that is important is called piston ring end gap. As shown in the photo to the left, it is the amount of clearance between the two ends of the compression rings. This clearance should always be checked with a feeler gauge and compared to the manufacturer's specifications. As the compression rings wear over time, this end gap increases. As it increases, more compression gases escape. This causes the combustion to be less efficient as well as having increased crankcase

pressure.

Product Name: Crankshaft Bearings

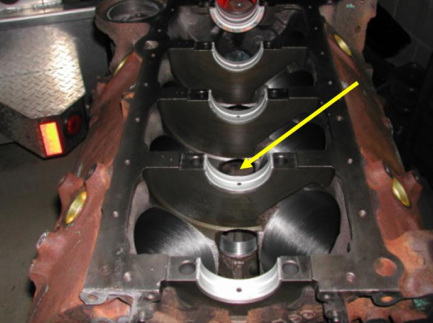

Product Description: When rebuilding an engine, new crankshaft bearings are usually installed. The photo to the left shows new crankshaft bearings installed on an engine that is being rebuilt. Bearing clearance can be checked and compared to manufacturer's specifications. This is done by using a small plastic thread called Plastigage, which comes in different diameters. The clearance is checked by placing the plastigage on the bearing surface. Then the crankshaft is installed along with the bearings caps and torqued to specifications. The bearing cap is then removed and the width of the squashed plastigage is measured. This measurement then translates to a specific clearance which can be compared to manufacturer's specifications.

Product Description: When rebuilding an engine, new crankshaft bearings are usually installed. The photo to the left shows new crankshaft bearings installed on an engine that is being rebuilt. Bearing clearance can be checked and compared to manufacturer's specifications. This is done by using a small plastic thread called Plastigage, which comes in different diameters. The clearance is checked by placing the plastigage on the bearing surface. Then the crankshaft is installed along with the bearings caps and torqued to specifications. The bearing cap is then removed and the width of the squashed plastigage is measured. This measurement then translates to a specific clearance which can be compared to manufacturer's specifications.

Product Name: Freeze Plugs

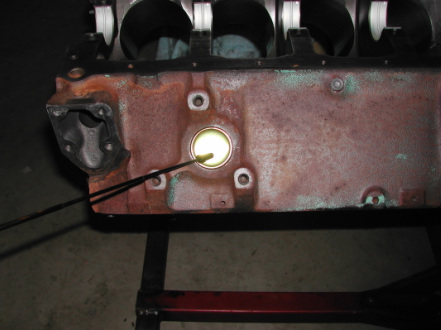

Product Description: Freeze plugs, sometimes called core plugs, are shown in the photo to the left. The plugs close the holes where the foundry core sand has been removed at the foundry. They also protect the engine block from cracking if the coolant freezes because of the lack of antifreeze. When the coolant freezes it expands. The expansion causes the freeze plugs to pop out, protecting the cylinder block from cracking. Several freeze plugs are located on the block as well as on the cylinder heads. During an engine overhaul, the old plugs are removed and new plugs are pressed in place. It is extremently important to make sure the plugs have a sealant and are pressed evenly into the core plug hole or leakage may occur.

Product Description: Freeze plugs, sometimes called core plugs, are shown in the photo to the left. The plugs close the holes where the foundry core sand has been removed at the foundry. They also protect the engine block from cracking if the coolant freezes because of the lack of antifreeze. When the coolant freezes it expands. The expansion causes the freeze plugs to pop out, protecting the cylinder block from cracking. Several freeze plugs are located on the block as well as on the cylinder heads. During an engine overhaul, the old plugs are removed and new plugs are pressed in place. It is extremently important to make sure the plugs have a sealant and are pressed evenly into the core plug hole or leakage may occur.

Product Name: Pistons

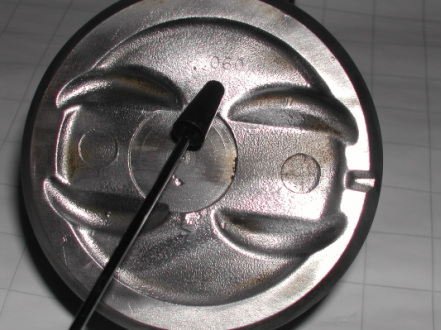

Product Description: Pistons are used to help transfer the power and expansion of the combustion into downward movement, through the connecting rod, to the crankshaft. During an overhaul, pistons should be cleaned and checked for cracks. Also, if the cylinders have been bored out to a larger size, it should be shown on the top of the piston. Looking at the photo to the left, note the .060 stamped on the top of the piston. This means that when the engine was rebuilt, the cylinder bore was bored out .060 inches. This also means that larger pistons are needed. If new pistons need to be purchased, they also have to be .060 inches oversize as well.

Product Description: Pistons are used to help transfer the power and expansion of the combustion into downward movement, through the connecting rod, to the crankshaft. During an overhaul, pistons should be cleaned and checked for cracks. Also, if the cylinders have been bored out to a larger size, it should be shown on the top of the piston. Looking at the photo to the left, note the .060 stamped on the top of the piston. This means that when the engine was rebuilt, the cylinder bore was bored out .060 inches. This also means that larger pistons are needed. If new pistons need to be purchased, they also have to be .060 inches oversize as well.

Product Name: LIfters/Camshaft

Product Description: During an engine overhaul, the lifters and camshaft should be replaced. When replaced, the lifters and camshaft must be "broken-in" together. In fact, during the first 20 minutes of running an engine after rebuilding, the camshaft and lifters will mate with each other. It is important as shown in the photo on the left, that the correct lubricant be used during installation to enhace break-in. The camshaft manufacturer will provide this lubricant (see arrow) when purchasing the lifters and the camshaft. Although the procedure is not complicated, it is best to always follow the manufacturer's suggested procedure to correctly break-in a new set of lifters and a camshaft.

Product Description: During an engine overhaul, the lifters and camshaft should be replaced. When replaced, the lifters and camshaft must be "broken-in" together. In fact, during the first 20 minutes of running an engine after rebuilding, the camshaft and lifters will mate with each other. It is important as shown in the photo on the left, that the correct lubricant be used during installation to enhace break-in. The camshaft manufacturer will provide this lubricant (see arrow) when purchasing the lifters and the camshaft. Although the procedure is not complicated, it is best to always follow the manufacturer's suggested procedure to correctly break-in a new set of lifters and a camshaft.

Back to Product Guide